CABLE GLAND EMV

CABLE GLAND FOR LOW LEAKAGE CURRENTS

EMC cable glands

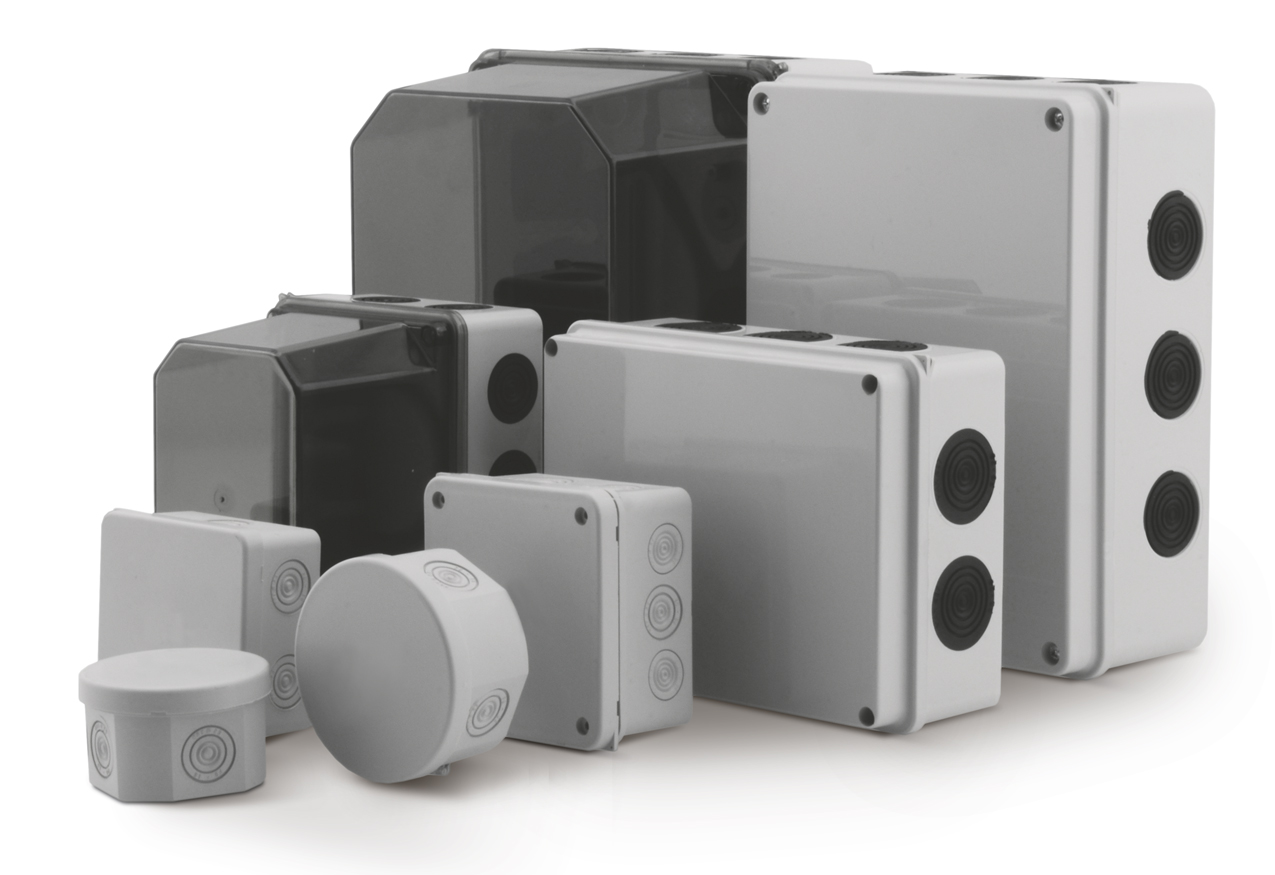

BOXEXPERT offers enclosures for various applications as well as accessories for special applications. Electromagnetic compatibility (EMC for short) is a special topic, especially in the field of electrical drive technology and sensor technology.

A magnetic field is formed around a current-carrying conductor. If the magnetic field lines overlap the field of another conductor, undesirable electrical or electromagnetic effects occur in the second circuit. With increasing complexity and the growing degree of sensor technology and microelectronics, the phenomenon of EMC increasingly leads to disturbances of the overall system.

To prevent this, in EMC-critical applications it is necessary to conduct the current correctly to the housing via the cable shield. In addition to the Treva and Alster metal enclosures, which are particularly suitable for EMC operation, BOXEXPERT also offers appropriate cable glands for applications with low to medium leakage currents as well as for high leakage currents, which frequently occur in electromobility and the use of frequency converters.

Cable gland for lower leakage currents

In the cable gland for low leakage currents, the shield contact is made via a spring system inside the lower part. The spring is attached to the cable shield and inserted behind the sealing insert. Since the contact is made via a clamp, disassembly is possible without destroying the contact. A modular system can be used for the composition of the cable gland. This allows you to freely choose which sealing insert and pressure nut to use. For the sealing inserts, for example, a choice can be made between different materials (e.g. NBR, TPE, FPM), and variants such as a hose fitting, trumpets, anti-kink nuts or a standard pressure nut are possible as the upper part. The principle of the gland is based on the compression technique, in which the sealing insert is pressed around the cable by tightening the compression nut.

MODEL OVERVIEW

| Order number | Thread dimension | Clamping range internal use (MM) | Clamping range external use (MM) | Height upper part (MM) | Thread length (MM) |

|---|---|---|---|---|---|

| BKECMM12-35 | M12x1.5 | --- | 3.5-5.0 | 22 | 5 |

| BKECMM12-50 | M12x1.5 | --- | 5.0-6.5 | 22 | 5 |

| BKECMM16-60 | M16x1.5 | 6.0-8.0 | 8.0-10.5 | 25 | 5 |

| BKECMM20-80 | M20x1.5 | 8.0-11.0 | 11.0-15.0 | 27 | 6 |

| BKECMM25-125 | M25x1.5 | 12.5-16.0 | 16.0-20.5 | 33 | 7 |

| BKECMM32-170 | M32x1.5 | 17.0-21.0 | 21.0-25.5 | 33 | 8 |

| BKECMM40-240 | M40x1.5 | 24.0-28.5 | 28.5-33.0 | 38 | 8 |

| BKECMM50-330 | M50x1.5 | 33.0-37.0 | 37.0-42.0 | 42 | 9 |

| BKECMM63-400 | M63x1.5 | 40.0-46.0 | 46.0-52.0 | 42 | 10 |

CABLE GLAND FOR HIGH LEAKAGE CURRENTS

Cable gland for high leakage currents

The cable gland for high leakage currents consists of three elements in the lower part. The actual lower part, a contact ring and an intermediate element. The shield is placed over the contact ring and tightened using the intermediate element. By tightening on the block, the assembly is gentle on the screen. In the front area of the cable gland you will find a sealing insert and a pressure nut from the construction kit. This means that you can also be flexible in the implementation of this screw connection. The 360° shield contacting with lowest contact resistance and transfer impedance enables the transmission of highest leakage currents, such as those found in electromobility. Despite the intermediate element, the fitting has a compact overall height. The screw connection also works by means of compression technology.

Overall solution

BOXEXPERT will gladly take over the implementation of an entire enclosure system. We advise you on the choice of enclosure, electrical components and the selection of the optimum cable gland.

MODEL OVERVIEW

| Order number | Thread dimension | Clamping range internal use (MM) | Clamping range external use (MM) | Shield diameter (MM) | Inner diameter (MM) | Height upper part (MM) | Thread length (MM) |

|---|---|---|---|---|---|---|---|

| BKPCMM16-60 | M16x1.5 | 6.0-8.0 | 8.0-10.5 | 9.3 | 8.2 | 28 | 5 |

| BKPCMM20-80 | M20x1.5 | 8.0-11.0 | 11.0-15.0 | 13.4 | 11.9 | 32 | 6 |

| BKPCMM25-125 | M25x1.5 | 12.5-16.0 | 16.0-20.5 | 18.7 | 17.6 | 36.5 | 7 |

| BKPCMM32-170 | M32x1.5 | 17.0-21.0 | 21.0-25.5 | 23.8 | 22.1 | 38.5 | 8 |

| BKPCMM40-240 | M40x1.5 | 24.0-28.5 | 28.5-33.0 | 30.4 | 29.5 | 42 | 8 |

| BKPCMM50-330 | M50x1.5 | 33.0-37.0 | 37.0-42.0 | 38.7 | 37.7 | 44.5 | 9 |

| BKPCMM63-400 | M63x1.5 | 40.0-46.0 | 46.0-52.0 | 48.6 | 46.6 | 49 | 10 |

| BKPCMM75-500 | M75x1.5 | 50.0-56.0 | 56.0-63.0 | 59.7 | 57.9 | 51 | 11 |

| BKPCMM80-580 | M80x2.0 | --- | 58.0-65.0 | 62.0 | 59.8 | 58 | 12 |

| BKPCMM85-630 | M85x2.0 | --- | 63.0-70.0 | 67.0 | 64.7 | 58 | 12 |

You have questions?

SEND US YOUR MESSAGE

[contact-form-7 id="3931" title="popup contact form"]

CONTACT INFORMATION

Follow us on our social media channels and get informed about new products.